Surface Finishing

Our proprietary approach to the surface quality of your part positively impacts biocompatibility, fatigue and corrosion. Our surface treatment methods include:

-

Electropolishing

-

Microblasting

-

Mechanical Polishing

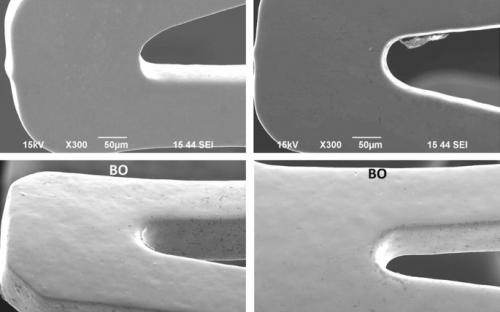

Electropolishing

Electropolishing is a state-of-the-art surface finishing process for medical implants, such as Stents and Filters. We at Synlas are one of the pioneers of electropolishing of Nitinol and have applied our proprietary electropolishing process to well over 1 million Self Expanding Stents.

- HAZ (Heat Affecting Zone) is removed and surface overall smoothed

- Surfaces have very high biocompatibility

- Metal fatigue is greatly reduced

- Corrosion behavior is improv

- The achievement of excellent edge rounding

- ed compared to non-treated or mechanically polished surfaces (Trepanier et al)

Mircoblasting

At Synlas, we have developed an automated micro blasting process, using a very fine-grained abrasive. This allows even the smallest of kerfs and slots to be blasted. Because an agglomeration does not appear from this processing, a very homogeneous mass removal can be obtained. The micro-blasting process is commonly used as a pre-treatment before electropolishing.

Mechanical Polishing

Mechanical polishing or barrel finishing is a surface treatment method used as a pre-treatment before electropolishing or for applications where the high quality of an electropolished surface is not required. Examples are short term medical implants and devices where a subsequent covering process is performed.